Solutions

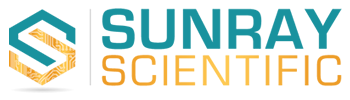

ZTACH® ACE Z-Axis Pressure-less Anisotropic Conductive Adhesive

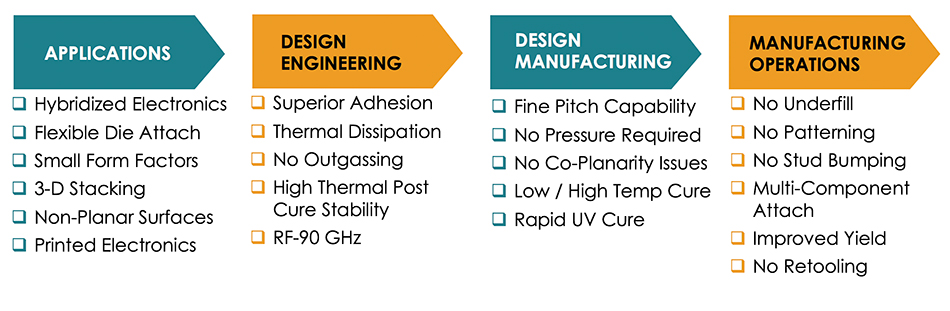

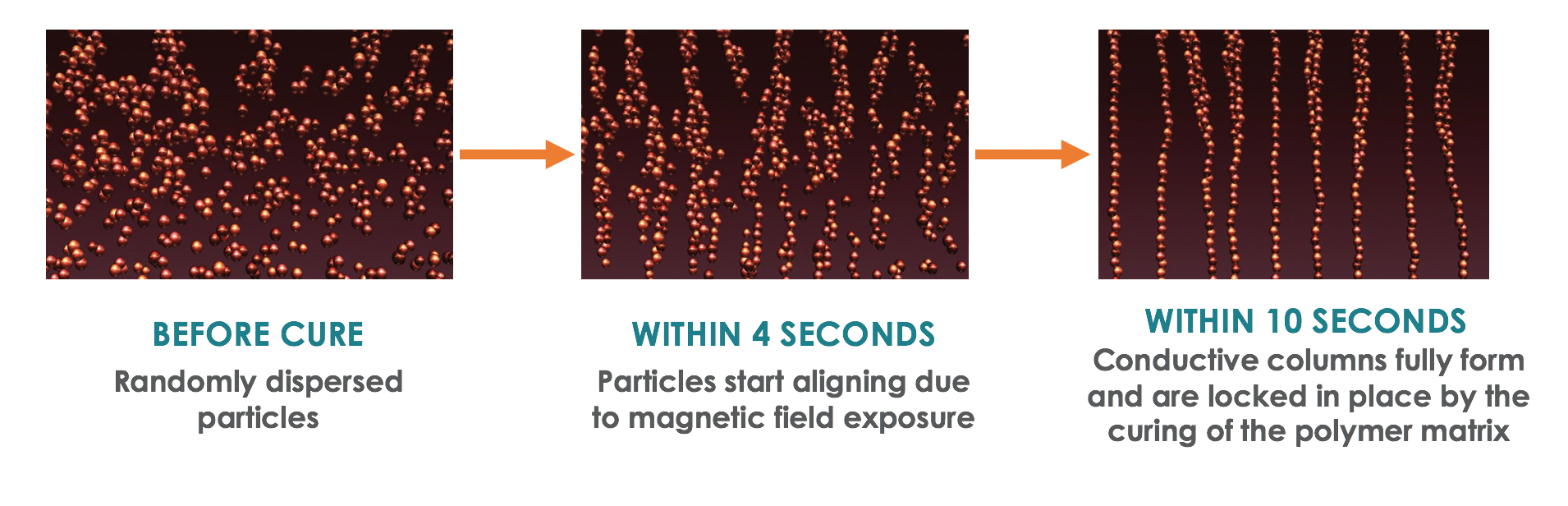

ZTACH® ACE is applied via automated syringe dispense or open aperture stencil without any pressure, and once applied to our patented ZMAG® Magnetic Pallet, can be cured either with heat at low temperature (80˚C to 160˚C) or with UV in a magnetic field. The results in the self-assembly of conductive Z-Axis columns at regular intervals throughout the adhesive thickness. The columns create electrical and thermal interconnection in the Z-Axis, while maintaining electrical insulation in the X-Y plane. After formation, the columns maintain their structure due to immobilization within a now rigid polymer matrix.

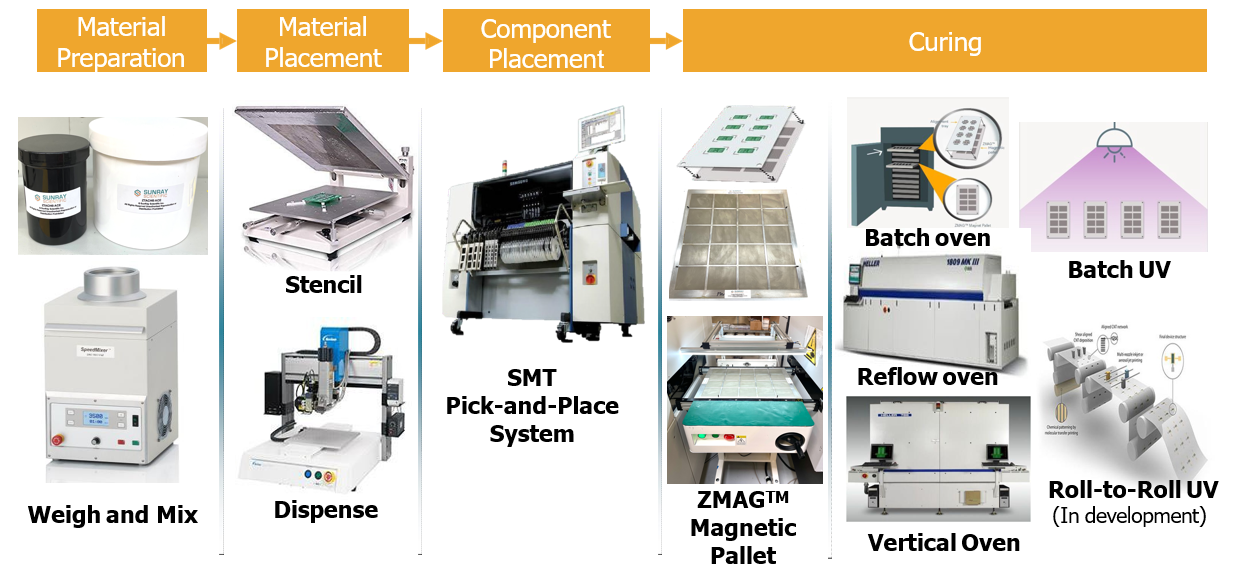

| Parameter | ZTACH® ACE | No-Lead Solder | ACF |

|---|---|---|---|

| Curing Temerature (˚C ) | 80 – 160 or UV | 250 – 340 | 130 – 150 |

| Feature Size (microns) | < 100 | < 50 | > 150 |

| Z-Axis Connection Resistance (mOhms) | 7 – 20 | < 7 | 20 – 1000 |

| X-Y Insulation Resistance (0hms) | > 1011 | < 1010 | > 1010 |

| Thermal Conductivity (W/m-k) | 1.4 – 1.8 | 60 – 100 | 0.5 – 5 |